having the right item in the right quantity

at the right time at the right place

Mallik, Susan (2010)

The Handbook of Technology Management

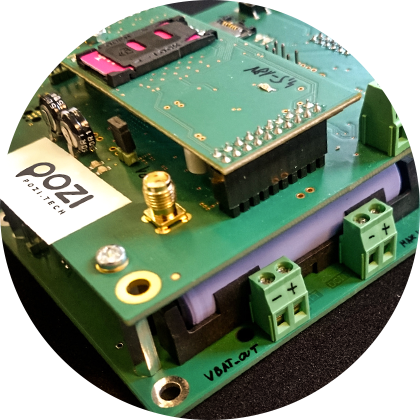

Pozi addresses the most important bottleneck of industrial production efficiency: logistics.

It identifies and accurately tracks the position and movement of objects in any type of indoor or outdoor environment, in real time, with utmost precision.

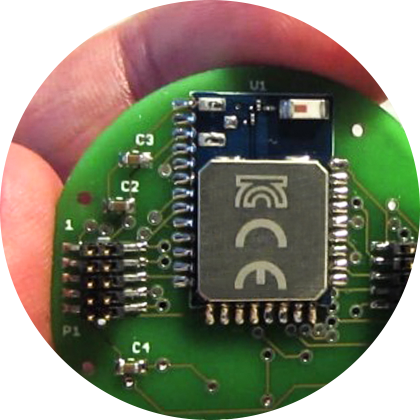

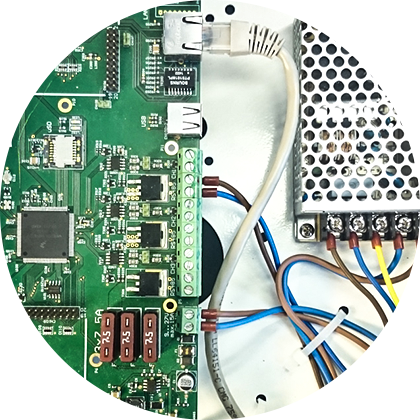

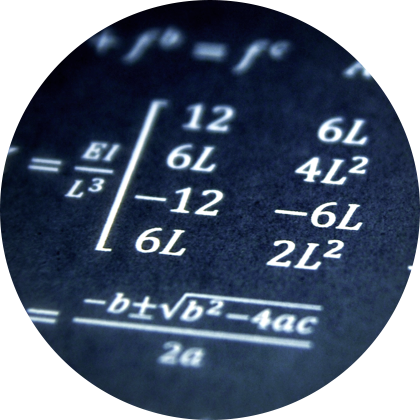

Pozi utilizes all currently available identification and positioning technologies to perfectly match every production environment.

We are also actively researching the next generation of platforms, committed to keeping our leading position in the industry.

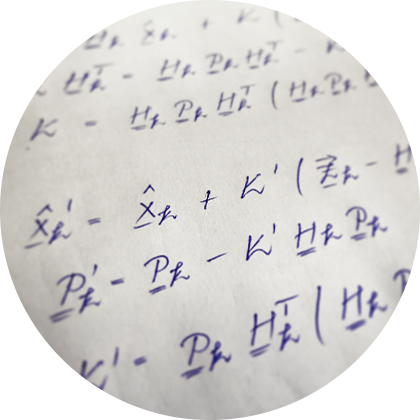

Pozi’s patented algorithm provides accurate location with 75% less measurement actions than traditional trialteration. This allows:

Our extendable multipurpose backbone infrastructure can accumulate all available identification and positioning technologies and platforms. As a result the RTLS system can be extended infinitely both in size and in terms of available technologies.

The output of Pozi is provided through various channels and platforms that match the type, place and purpose of its utilization:

Pozi increases the efficiency of production and warehousing targeting several aspects of logistics simultaneously:

An Enthusiastic

Development Team

Lawyer, entrepreneur, product launcher, technology ecosystem expert and market positioning professional

Engineer, technology researcher, development director and guru of all gadgety matters